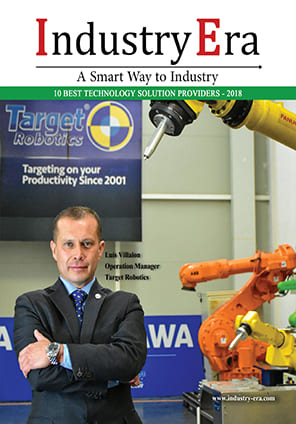

Luis Villalon, Operation Manager

Experts in Robotics

Luis Villalon had a vision of an automation future, he knew robotics will culminate into one of the main technologies of automation and hence incorporated Target Robotics. Luis was right, today there is no complete automation without robotics, further more, automation is just one part of robotics. One can say that since the beginning, Target Robotics’ focus has been on robotics as the core business, developing expertise on industrial processes done by robots. The company is a leader in Mexico in providing turnkey solutions from design engineering and simulation all the way through installation, start-up and project management designed by experienced engineers focused mainly on industrial, applications.

Target Robotics culminated into a market leader in technology-driven solutions providing expertise in automated processes with robots because they understood automotive industry leads the manufacturing automated processes. Hence, the company keeps 50 percent of the business in automotive industry, and 50 percent in general industry, mainly food and beverages. In that way, Target Robotics stakes all new technology, manufacturing concepts, innovations process and procedures, high standards, project developing methodology, new components, devices and safety standards, from the automotive industry, and applies it into the general industry, becoming one of the leaders in general industry.

" Target Robotics culminated into a market leader in technology-driven solutions providing expertise in automated processes with robots because they understood automotive industry leads the manufacturing automated processes."

Target Robotics has two main strategies that drives them towards success: people and concepts. Target Robotics have hired just graduated engineers from best public universities of Mexico and trained them single handedly to transform them into experts. The other success strategy is Target Robotics concepts, called “simple automation”. Target Robotics copies the operator movements and emulates it via robots, using all robot functionality, flexibility and advanced software functions, giving features like tact sense and vision capabilities, using all this data to make decisions and acquiring high performance. “Simple automation” also avoids the use of external PLC, using the robot processor. Other main feature that “simple automation” have is to avoid the use of pneumatic elements, external motors, gears, cams, shafts, bands, chains, and any mechanical subsystem, trying to let the robot to make all the job.

This year Target Robotics developed a multi-functional robotic system to un-palletize, orient and wash plastic trays; align and accommodate many types of products in different defined configurations and load it inside the tray; then stack and palletize the trays with the product. All the processes in one system, using all software robot features like decision maker based on vision system, auto-recovery functions, safety compliance, auto diagnosis, plug & play, small footprint and autonomous. Before this new disruptive system, the customer usually had to purchase five stations, one for each process, full of mechanisms. The cost of these five stations was three times higher, the footprint was ten times bigger and required four operators per shift. The power consumption, spare parts, complexity to adjust and low flexibility was a nightmare. Through Target Robotics customers can reduce the return of investment from 4.5 years to less than one.

Due the necessity to research and develop an enhanced robotic version of the prevalent manufacturing systems,and to re-invent many industrial processes, robotizing it, Target Robotics will build, in 2019, the Target Robotics University, where hundreds of design engineers will get the acknowledge of innovation, disruptive, exponential and continuous changing technology to develop robotics systems for all kind of industries and all type of industrial process. In the coming years, this will be the origin of a research, development and manufacturing center for the new generation of robotics systems, that will be competitive all over the world.

Company

Management

Luis Villalon

Operation Manager

Description

Target Robotics provides developing turnkey solutions from design engineering and simulation to the whole installation process, star-up and project management.