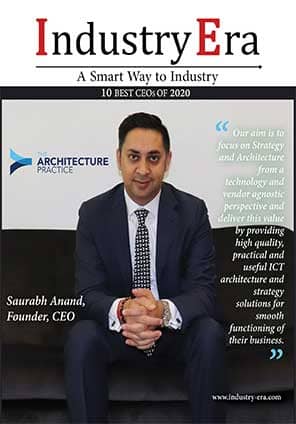

R. Charles Murray

CEO of PPi Technologies GROUP

“The Pouch & Packaging Experts”

R. Charles Murray arrived from South Africa 30 years ago with his family into Chicago and was drawn by weather concerns to sunny Florida where he started the company in Sarasota, Florida. His background is working for the largest brewery in Africa that had taught him that doing the total system meant he could deliver what the customer wanted, when they wanted it and be responsible for the project. Pain points were convincing the German, Italian, Polish, South Korean, South African, Spanish, and Japanese to become partners in supplying their top brands under the PPi Technologies Group name. Today all these companies are number one machinery suppliers in their markets in their countries.

"The PouchPac Innovations LLC machinery patents hold these companies together and they enjoy much success."

The PouchPac Innovations LLC machinery patents hold these companies together and they enjoy much success. The plan was one packaging system with all top brands, patent protected for the end user benefit and available throughout the world. However, as the market changed individual use products grew and these single use products opened up VialPaQs, TubePaQs and StickPaQs flexibles. The need to have no human contamination and, no underweight products led to adding checkweigher and metal detector combination machines and now x-ray machines to the product lines. To compliment and finish the total system, required robot AI and cartons/shipper erectors that were flexible and could handle many shapes of products into secondary case packaging. So, they were the first USA packaging machine company to offer the top brands from six top global partners. This took the company from being dependent on one machine sales to a total system supply and taking responsibility of the filling and packing line machines and, many have now followed this concept.

The day the COVID-19 virus became news, Charles set about making in2itiv™ hand sanitizers for the marketplace. The hand sanitizers are not just packed in bottles, but also pouches for refilling and a world first in an AIROFILL™ air filled bottle from Netherlands that can be aimed in all directions to “spray and go” anything likely to be contaminated. He has also developed another world first in that nurses etc. sanitize many times a day so he encouraged their Italian partner to develop a waterless soap sanitizer hand washer and added a hand cream to protect the skin after sanitizing. All packed in an easy to carry and use when needed in a twin VialPaQ™.

At the company, offices, cafeteria, and workspaces are organized to ensure social distancing. For all visitors, temperature control, masks, gloves, and sanitizer are available on arrival. “We have handles, tables, and bathroom cleaning non-stop all day and staff are checked for the COVID-19 virus if they suspect contact with a proactive case,” adds Charles.

To extend the shelf life of many fresh products packed into pouches, Charles and his team of talented experts developed and patented diving nitrogen lances to remove oxygen and this keeps products fresh for longer periods. They developed that if a pouch does not open during filling, then it circles one more time so pouch can be filled and reduced waste. Charles and his team patented many pouch shapes that customers could easily recognize their brands. They developed and patented twin compartment pouches, dry product in one and liquid in another with a breakable seal you mix and product ready to use. Today, the company has 120+ patents and allows customers to use these as an advantage in the marketplace.

According to Charles, the future – will be a fight over single use or multi-use packages. One lesson that has been learnt from COVID-19 is single use plastic is back again. So, our leaders will have to promote syn gasification to handle the plastic garbage/land fill problem. “The second will be that more and more companies are thinking why I am packing goods - let us get a contract packer to do this while we concentrate on sales,” says Charles. “With online purchasing as the next big item for brands you need products made to be shipped and maintain brand image in the home as there is no store shelf to choose from.”IE

Company

Management

R. Charles Murray

CEO of PPi Technologies GROUP

Description

Founder & CEO R. Charles Murray, "Everything we produce should be natural, wellness and not harm the way you look." PPi Technologies Group was formed to sell machinery that manufactures pouches with slider and press-to-close zippers from printed laminated roll stock films and also offers prefabricated pouches with spout fitments. A first for the North American market! An important part of the original business plan was not to just sell machinery to customers, but to help develop 21 market segments covering, for example, food (including fresh and microwave), beverage, pet foods, healthcare and chemical segments amongst others.